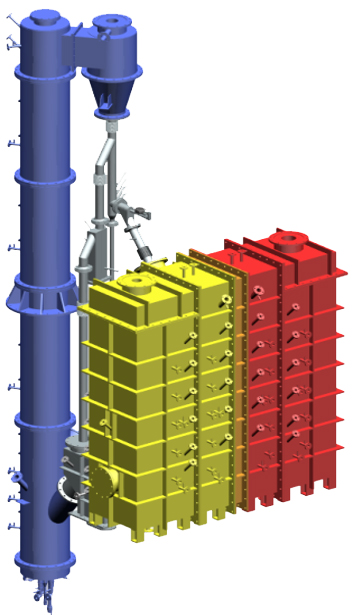

A 300 kWth pilot plant for investigation of indirect calcination via heat pipes was erected, commissioned and successfully operated at Technische Universität Darmstadt. The feasibility of the IHCaL process using heat pipes for the heat transfer from the combustor to the calciner was demonstrated within four comprehensive test campaigns with more than 500 hours of total operation with coupled circulating fluidized beds and over 300 hours of stable CO2 capture at various operating points.

Within the ANICA project the IHCaL process will be tested in a 300 kWth pilot plant under realistic conditions of cement/lime applications. Typical fuels of lime and cement plants (i.e. coal and SRF) will be used as fuel in combustor. A real flue gas from combustion of coal and SRF (produced in the combustor) will be fed to the carbonator. Additional CO2 from tanks will be added to flue gas from coal and SRF to account for process CO2 released during calcination in a cement plant. Typical raw materials for cement production will be used as sorbent in dedicated tests.