Motivation

In order to decrease the global CO2 emissions, sustainable and economical processes need to be applied in the energy and carbon-intense industry sectors. The production of lime and cement is one of the major sources of CO2 emissions in the industry sector. During the production of lime and cement, natural Calcium Carbonate (CaCO3) is calcinated to Calcium Oxid (CaO). The necessary heat for the calcination is mainly generated by combustion of fossil fuels. Process and combustion CO2 from limebased production accounts for around 8% of global fossil CO2 emissions.

The ANICA Project

The ACT-project ANICA (Advanced Indirectly Heated Carbonate Looping Process) develops efficient concepts for CO2 capture in cement and lime production plants by means of indirect heating. The novel concepts aim at low energy penalty and high integration potential of mass and energy streams into such plants. Compared to the standard oxy-fired carbonate looping (CaL) process, no air separation unit (ASU) is needed for the IHCaL process, since the heat for calcination is transferred via heat pipes, as shown in figure 1. The indirect heating facilitates the purity of the separated CO2 stream, which leads to less costs of post-treatment for further usage. Furthermore, synergies in the IHCaL process and

production process of cement and lime are offered, since same solid materials are used in both processes. A sorbent utilization of more than 90% is expected to be achievable with the novel integration of IHCaL process. When combining the utilization of waste derived fuels with a high biogenic fraction with CO2 capture, this novel concept offers a high potential for net negative CO2 emissions.

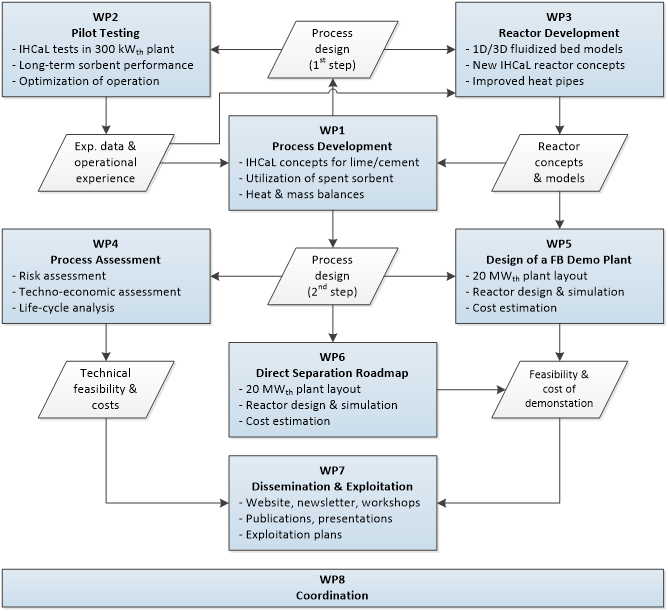

The project is divided in eight work packages (WP), as shown in Figure 1.