The objective of Work package 5 is to provide the basic design of a semi-industrial IHCaL demonstration plant with fluidized bed reactors on a cement production site and the associated cost estimation as a basis for an investment decision.

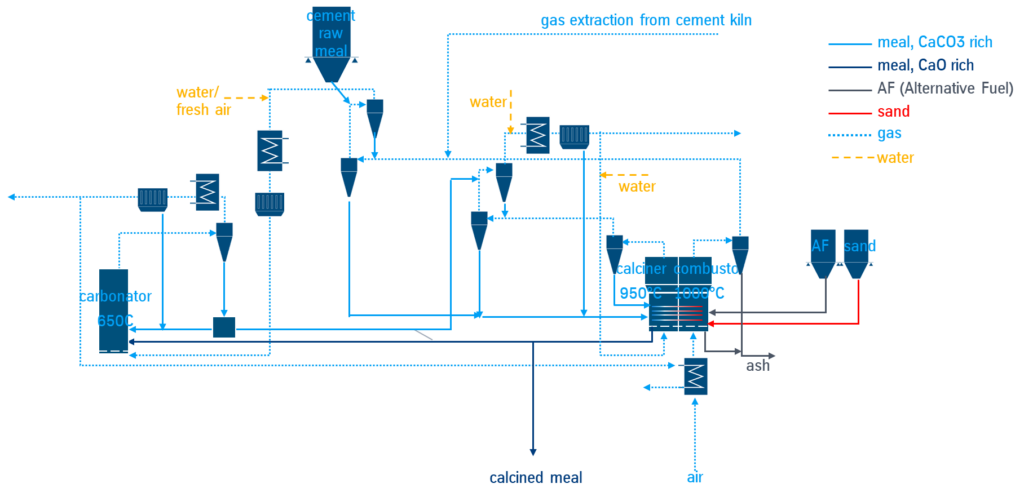

In the first part of work package 5, preliminary concepts for the layout of the demonstration plant based on fluidized beds were developed. The sorbent used in the cycle between calciner and carbonator is cement raw meal, consisting of primary limestone, chalk and clay or their natural blend, marl. The thermal optimization of the plant demands the heat extraction from different gas and solids streams. The feasibility of the different heat extraction points is being validated with literature data and practical experience of suppliers and operating companies. The correspondent flow sheet is being continuously optimized. The next step is the optimization of the flow sheet based on the heat and mass balance of the process.