During the first half of the project, the pilot plant was adapted to be prepared for the testing under cement and lime plant conditions. On the basis of preliminary heat and mass balances, operational modes of the existing equipment have been identified and the design conditions for the new equipment were elaborated. Concept, basic and detailed engineering of the major upgrades of the pilot plant, namely the flue gas path and solid feeding system, have been performed. In order to improve the operability of the plant, smaller modifications like purging, sampling and feeding system of the sorbent (CaO/CaCO3) are being installed.

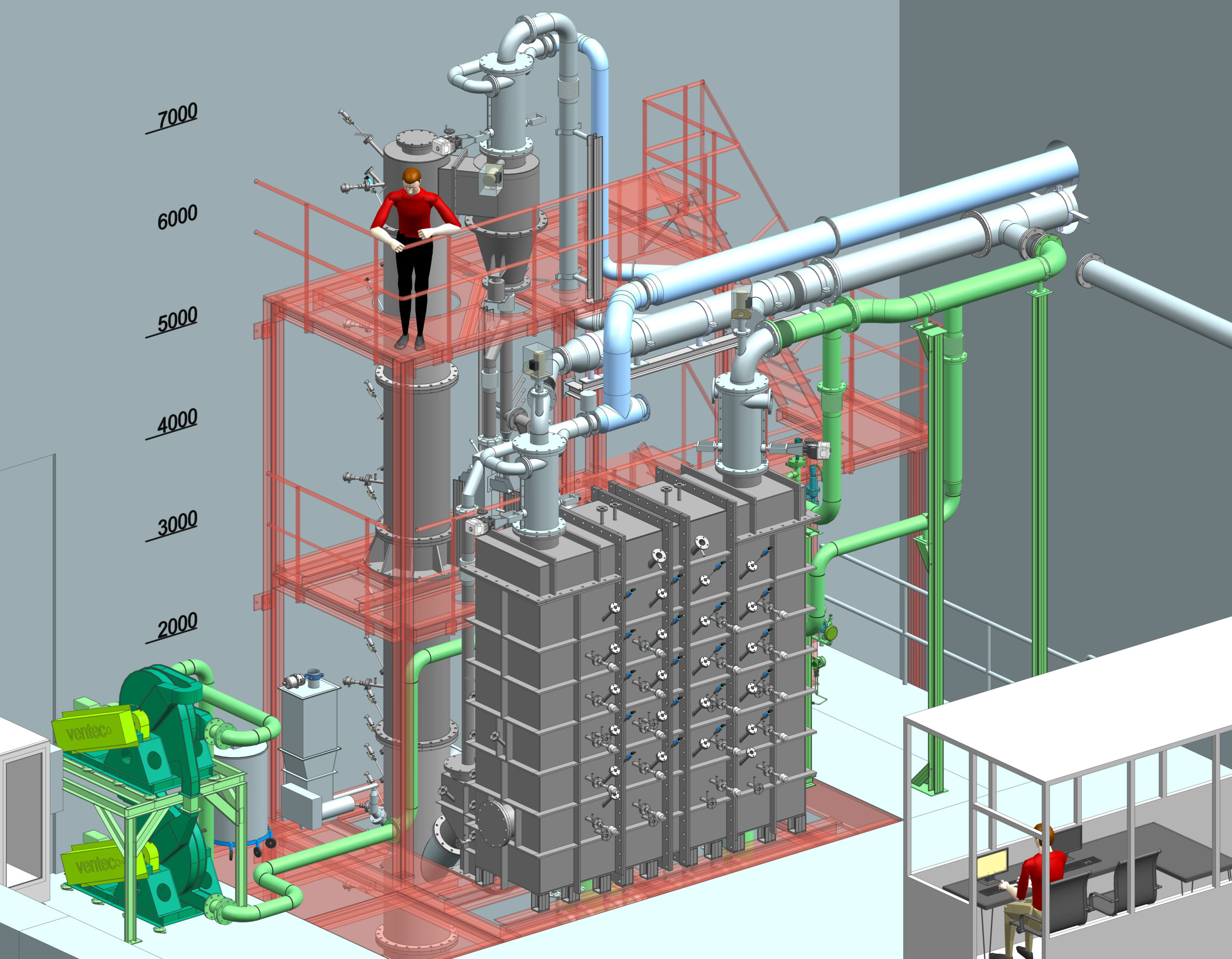

The major changes that have already been implemented are illustrated in Figure 1.

The mechanical and electrical implementations of the upgrades are ongoing, while the cold commissioning of the components of the flue gas path is performed simultaneously.

The boundary conditions of the first test campaign under lime plant conditions are elaborated and the pilot plant is being prepared for these tests, aiming to deliver purged sorbent (CaO) to analyse it and assess its quality for lime applications.

While using cement raw meal as sorbent, proposed for the highly integrated solution under cement plant conditions, different challenges occurred, addressed in WP 1.5. Depending on these results and additional tests in batch conditions, e.g. investigations on hydrodynamic behaviour, operational modes for using cement raw as sorbent will be identified.

In the second half of the project, the solid feeding system will be installed and pilot tests performed. First experimental results are expected by the end of the year 2021.