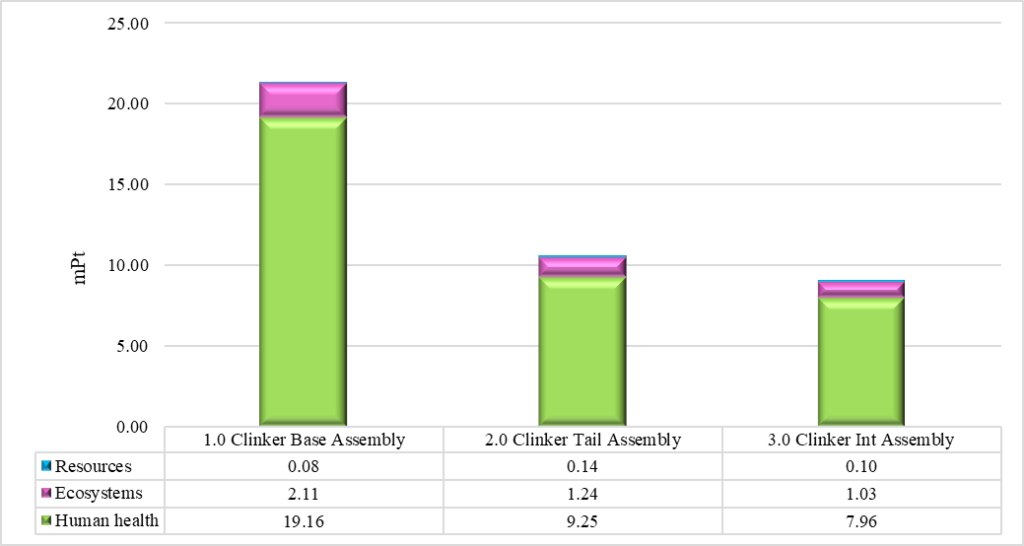

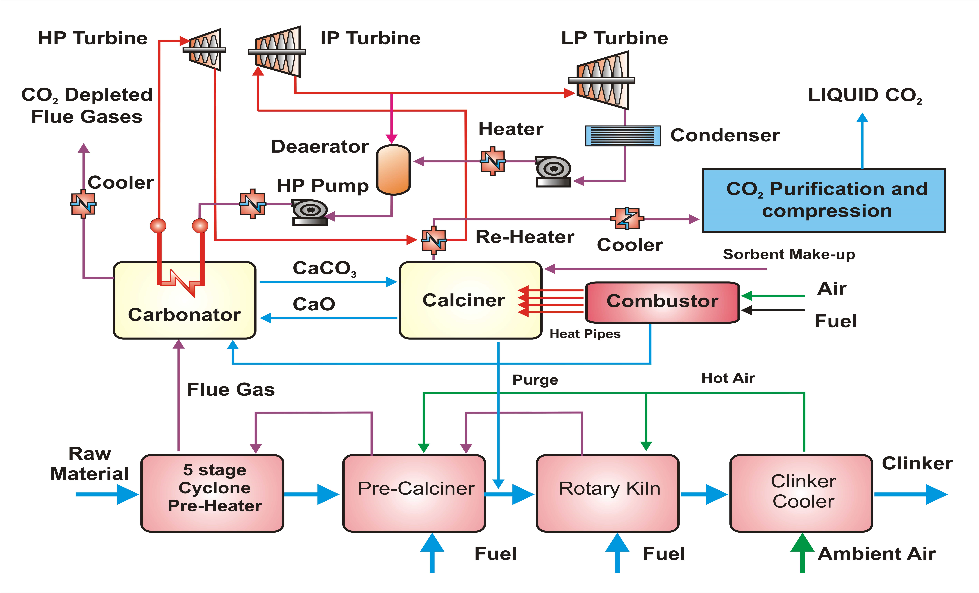

The ECLIPSE process simulator is used to carry out technical, environmental, and economic assessment study. Ulster University (UU) and ESTRA team has developed Block Diagrams of the cement plant, rotary lime kiln and double shaft lime kiln plants. Process modelling of reference plants without CO2 capture, IHCaL process, tail-end and fully integrated configurations are implemented. To date, boundary conditions for techno-economic assessment are specified properly. Mass and energy balance results using different feedstocks, including coal, SRF, lignite and petcoke have been generated. This information has also been fed to the tasks of LCA, risk assessment and techno-economic assessment. Based on input and output data identified the lifecycle assessment of the cement plant has been performed by using SimaPro software. A draft report of LCA for the cement plant is created and reviewed. The capital cost estimation for the cement and lime plants (reference cases) is carried out (using top-down approach).

The experiments with Powersim system dynamics software have been conducted on Monte Carlo risk analysis. The first object of study was the tail end solution of application equipped with the IHCAL process to lime production, in the tail end solutions shown for CaO Hellas and Kalkwerk Honnetal. First drafts of the qualitative risk analysis of the IHCAL in lime production based on the Failure, Mode, Effect and Criticality Analysis method have been made. Such initial tables have been created for the application of the risk analysis method to the integrated and tail end solutions studied for Kalkwerk Honnetal.